BRAZED PLATE

HEAT EXCHANGER |

Brazed plate heat exchanger

High temperature and pressure. Contrary to the traditional plate heat exchanger the

brazed plate heat exchanger does not contain rubber gaskets and can thus operate

continuously at the temperatures from minus 180°C up to plus 200°C.

The operating pressure can be as high as 30 bar.

Typical applications are:

- District heating, heating and ventilation.

- Solar heating and air conditioning units.

- Heating pumps and heat recovering units.

- Hydraulic and fuel oil units.

|

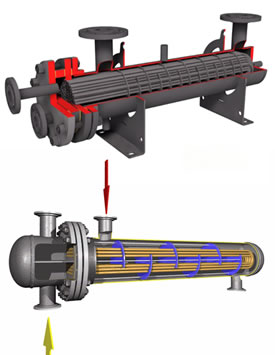

ALL WELDED PLATE AND

SHELL HEAT EXCHANGER |

Design and function of the heat exchanger:

This heat exchanger works in the same way as an ordinary tubular unit, however, it is

more efficient because plates have been used instead of tubes. The plates are laser / TIG

welded together to form a plate pack, which is then mounted inside a traditional cylindrical

shell.

Pressure rating:

PN16 / PN 25. Max temp.: Up to 250°C. The heat exchanger is produced

as an all welded exchanger or with flanges as shown on the photo below. This makes

manual cleaning possible. |

THE FRESH WATER

DISTILLER UTILLIZES |

The Fresh Water Distiller

utilizes the heat from diesel engine jacket cooling water to produce pure drinkable water

by evaporating sea water under high vacuum, enabling the feed water to evaporate at

temperatures below 48°C. Steam can also be used as the heat source instead of the hot

jacket water.

The Fresh Water Distiller is based on two titanium plate heat exchangers, acting as an

evaporator and a condenser respectively. |

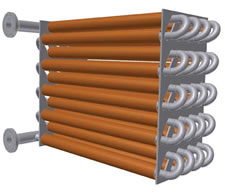

Shell and tube heat exchanger |

Shell and tube heat exchanger

Shell-and tube heat exchangers are most frequently used as oil preheaters for main

and auxiliary engines, burners and separators. |

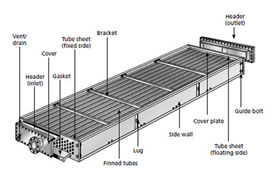

Economizer |

Economizer

- Waste heat recovery

- Air heat exchanger

- Air heater

- Air cooler

- Tube and fin heat exchanger

|

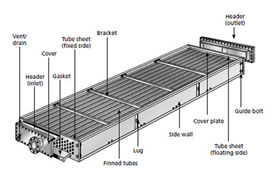

Finned tube heat exchanger |

Finned tube heat exchanger |